The applications of HitecUV lamps are many and diverse. Since UV is a clean and green technology, UV based systems are being increasingly used to replace chemical processes and reduce energy usage, carbon emissions, air and water pollution. Some of the applications where HitecUV lamps are used are:

In the printing industry UV cured inks and varnishes not only produce a higher quality finish but also eliminate the pollution that is caused by the use of solvent based inks and varnishes that release VOC (Volatile Organic Compunds) in the air. The UV inks and varnishes dry instantly on exposure to UV light so immediate post print processing is possible. HitecUV replacement lamps are available for almost all makes of Indian and imported printing & UV curing machines including:

- Sheet Fed Offset Printing

- Web Offset Printing

- Label & Narrow Web Printing

- Newspaper Printing

- Flexo, letterpress & Screen Printing

UV coatings are used in packaging printing to protect the ink from fading and to make the package more attractive. Its distinctive shine brings out the vibrancy of colours and reflects light in an eye-catching way. UV coating and printing is also used for high quality printing on three-dimensional packaging containers made of different materials. Low migration UV cured inks are used for food and cosmetics packaging. Applications include:

- Coating and printing on paper and cardboard packaging

- Printing on plastic packaging such as toothpaste tubes and cosmetic bottles

- Printing on glass bottles

- Coating and printing on metal cans used for beverages, beer etc.

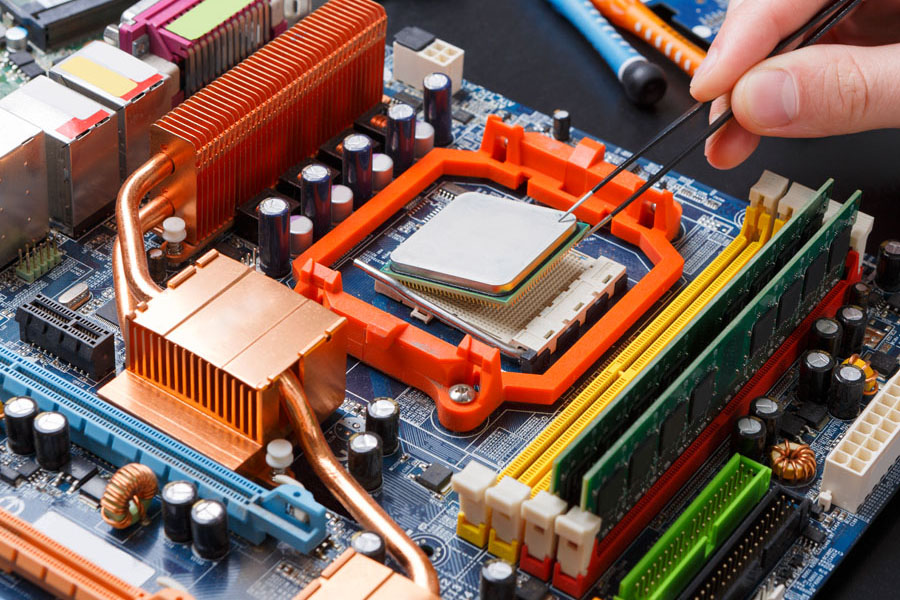

UV coating, bonding and curing is extensively used in electronics production for adhesive bonding and assembly, component marking, gasketing and sealing, potting, masking, encapsulating, and conformal coating. The UV curing process improves production rates without damage to sensitive electronic components. Applications include:

- PCB exposure and conformal coating

- Mobile Phones

- Wafers & Semiconductors

- Displays & Touch Screens

- Optical Films & Media

Manufacturers of a wide variety of wood products such as prefinished flooring, mouldings, panels, doors, cabinetry, particleboard, MDF, and pre-assembled furniture use UV curable fillers, stains, sealers, and topcoats (both clear and pigmented). UV curing is a low temperature curing process that significantly reduces finishing process times while providing superior durability due to improved abrasion, chemical, and stain resistance.

UV curing delivers enhanced product performance while increasing production rates for flooring manufacturers. Hard wood and PVC flooring manufacturers rely on clear UV curable topcoats for enhanced performance characteristics such as stain and scratch resistance, anti-slip and ease of cleaning.

UV cured resins are used to fill and seal cracks and small holes in marble and granite flooring.

Custom designs are screen printed and UV cured on ceramic flooring and wall tiles.

Environmentally friendly and energy saving water treatment and disinfection with UV includes treatment of ballast water, industrial process water, drinking water, municipal sewage and water for aquaculture, agriculture and horticulture.

Exhaust air from industries often contains pollutants such as solvents, VOCs and unpleasant odours which pollute the air and are subject to increasingly tough environment regulations. UV radiation is used to treat and purify the polluted air.

HitecUV lamps are used in UV systems for photochemical process steps in organic synthesis. In this process vitamins, hormones, fragrances and other valuable components are produced by synthesis with UV light. Photochemical synthesis has the advantage that often complex synthesis steps can be shortened, resulting in high yields and high purity. Applications include production of Vitamin D and the hormone dydrogesterone.

UV coatings, inks and adhesives are used on a wide variety of medical products including syringes, catheters, hearing aids, medication patches, hydrogels, filters, and test strips. UV cured materials provide biocompatibility, improved durability, lubricity, and chemical and scratch resistance. Medical product manufacturers needing to bond, seal, mark, and coat a variety of substrates find UV curing processes are consistent and reliable, helping them meet stringent industry quality requirements.

HitecUV lamps are used for the UV curing of automobile headlamp lenses and reflectors. Other applications include coatings on interior plastic parts, under-hood metal and plastic components, and even exterior glass, plastic and metal parts such as body trim. UV coatings and inks provide excellent scratch resistance, good adhesion, and chemical resistance for long lasting, durable coating and marking applications required in automobile exteriors and interiors.

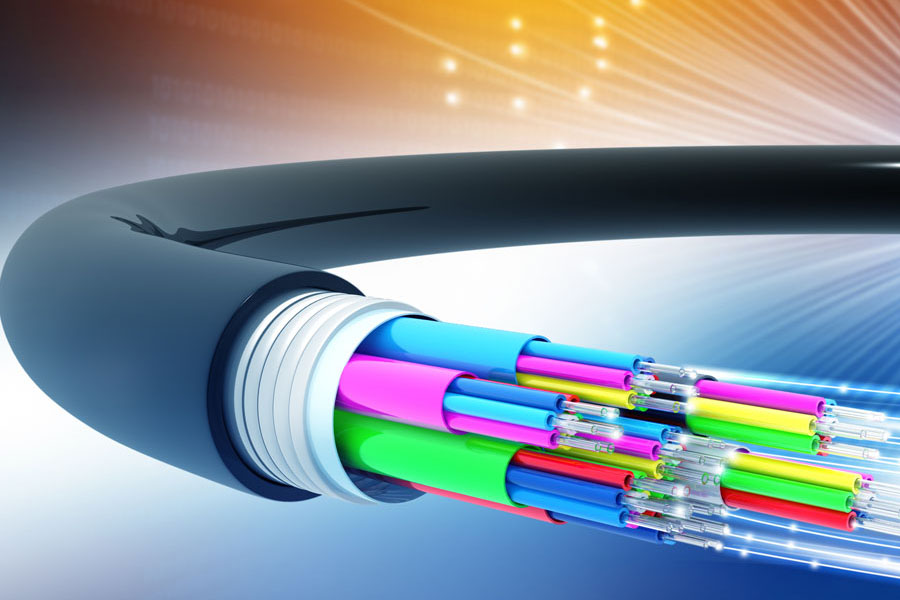

UV coatings provide protection, flexibility and strength to the optical fibre as it is drawn. UV inks are used to colour code the fibres and protect them from decomposition caused by cable gels. Ribbon matrix material, a UV curable polymer, encapsulates multiple optical fibres to create ribbon cable.

Finished fibre optic cables, as well as other types of wire and cable, use UV inks for labelling and marking identification on the outer sheath, usually plastic or rubber based, that protects the wire or cable core and facilitates installation.